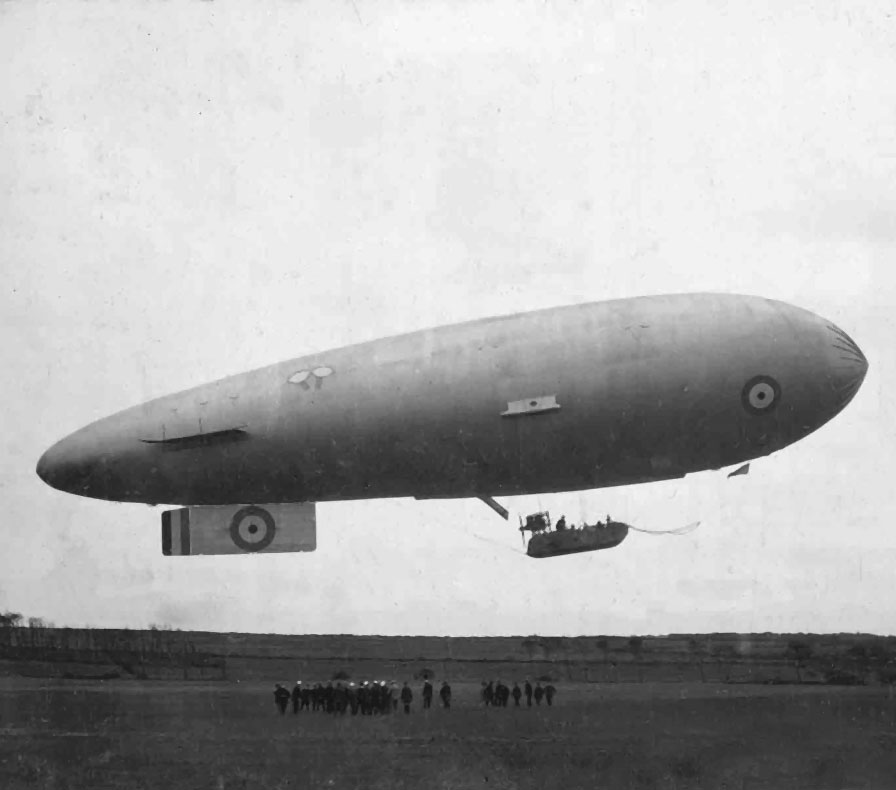

Acting as observers as well as active participants to the fleet’s battles, the Submarine Scout (SS) airships were much smaller than the NS-Class but still very successful. The last of the class were SS Zeros which were fitted with machine guns and proved popular with the crews. 77 of this class were constructed.

Even though they were much smaller than the NS-Class and with less endurance, the fundamentals and challenges of controlling a Zero were much the same. Warneford and Elliott, the officers of NS11, both had much experience with Zeros, from triumphs to hair-raising adventures. The account below, written by Captain F. W. Verry OBE, gives a fascinating account of flying a Zero.

Refuelling was normally carried out immediately after return from patrol. Gassing-up was carried out shortly before flight under the supervision of the coxswain, who also inspected the ship for frayed control cables, gas leaks and so on. Before leaving the shed the ship was ballasted up. This was done by loading the car with a full crew, or substitutes, dummy bombs of the same weight as the live bombs and ballast until the ship would just lift from the floor when the guys were cast off. The handling party was under the command of the pilot, or at large stations a landing officer. The size of landing party required depended mainly on the strength of the wind. With a wind of 10 to 20 mph about 30 men would be necessary, six on each guy and six on the car party.

The first necessity after leaving the shed was to get the ship head to wind as soon as possible. Most sheds had wind screens to protect the entrance from cross winds and the ship could be swung round into the wind before leaving the shelter of the screens. Sometimes it was necessary to take the ship out stern first into a wind blowing along the length of the shed. This meant turning the ship round through 180 degrees without having the benefit of any protection from the screens and required a large landing party and skilful handling unless the wind was very light. Once the ship was head to wind, handling on the ground presented no particular difficulties, except in very strong or gusty winds.

When well clear of the shed the two rope after guys were unreeved from the permanent wire guys and the forward guy only was used, the ship being allowed to swing like a weathercock about the forward mooring point. The duty of the car party was to steady the car and prevent it from bumping on the ground, but not to stop it swinging freely into the wind. The orders given by the officer in charge were: “Walk ship ahead” or “Walk ship (bodily) to port or starboard”, these orders being complied with by hauling on the forward guys.

When the ship was far enough away from the shed, the dummy bombs were replaced by live ones, the pilot replaced the rigger temporarily occupying the cockpit and with full crew on board the ship was again ballasted up. On the order “Ease up the guys” and “Hands off”, the guys were slackened and the car party let go of the car. Ballast was removed or added until the ship just lifted gently, indicating that she was a few pounds light, when the car and guys were again secured. The engine was then started up and the elevators set upwards at about 25 degrees by turning the elevator wheel backwards about a full revolution. As soon as the pilot signalled that he was ready, the officer or petty officer in charge of the landing party ordered “Lift up the car” and “Let go”. The final order was often given by a single note on a bugle to ensure that it was heard by all members of the landing party and the guys and car released simultaneously. The car party gave the car a final push upwards and the pilot immediately opened the throttle.

It was important to get steerage way on the ship as quickly as possible, particularly if the wind was gusty. Some care in opening up the engine was necessary, however, if the ship was at all nose heavy, as until the elevators took effect the first result of opening the throttle would be to dive the ship downwards. As soon as the ship had picked up a little speed a steep climb could be made, a rate of 1,000 feet per minute being attained without difficulty.

The pilot’s chief preoccupation during the climb was to keep the gas pressure from rising. if the ship was climbing at 1,000 ft per min., air or gas would have to be discharged at a rate of about 2,500 cubic feet per minute to keep the pressure constant. This meant hanging on to the air valve toggles if there was any air in the ballonets or the gas valve if the ballonets were empty. If gas had to be discharged, there would be a corresponding loss of lift, amounting to about 170 lbs for each 1,000 feet rise in altitude, and the ship would be constantly heavy to this extent if it had been in equilibrium on leaving the ground. The ship could be flown in this condition, the elevators being used to counteract the loss of buoyancy. At cruising speed fuel would be consumed at a rate of about 30 lbs per hours, so that the ship would again be in equilibrium after about five hours flying.

In normal level flight, the ship was flown on the pressure gauge by means of the elevators. In order to explain this more precisely, the pressure inside the envelope must be maintained at a constant level but this pressure is very sensitive to changes in atmospheric conditions. Changes in temperature or barometric pressure cause the gas to expand or contract and the pressure varies accordingly. If the changes are due to alterations of sunshine and cloud their effect is increased by the alternate warming and cooling of the envelope surface. It might be imagined that these frequent changes in pressure would make it necessary to use the valve and crab pot continually to release or blow in air to compensate for the variations. In fact this is unnecessary. Fortunately, the pressure is equally sensitive to small changes in altitude, so that the elevators could be used as a means of keeping the pressure constant. If the pressure rises for any reason, a slight downward movement of the elevators quickly restores it to normal. Similarly, an upward movement corrects a drop in pressure. All the pilot has to do is watch the manometer dial and keep the pointer within the prescribed limits by small movements of the elevator wheel. Although this involves almost a continuous watch on the instrument board, the pilot soon gets used to watching the dial out of the corner of his eye and has plenty of time left for his other duties. In rough weather, however, the manometer pointer gets much more restless and a closer watch is necessary. In addition to changes in temperature and barometer, the effect of rising and falling air currents have to be counteracted by the use of the elevator. In very turbulent conditions, the pressure may rise and fall so rapidly that air has to be valved or blown in to supplement the effect of the elevators, but this is not usually necessary.

The Zeros were handy and pleasant ships to fly in average weather conditions. Winds up to about 25 miles per hour were regarded as normal flying weather, but higher winds were often encountered on patrol. Steering with the large rudder then became hard work, particularly if conditions were bumpy. The normal flying pressure was 25 mm of water, equivalent to about 5 lbs per square foot at the bottom of the envelope. If the pressure rose above 30 mm, the air valves started to blow off automatically, while if it reached 40 mm the bottom gas valve also opened. Pressure was never allowed to reach this point if possible, or to drop below 20 mm, although in stormy conditions both extremes were exceeded involuntarily.

Controllability in the vertical plane was affected both by the state of buoyancy of the ship and by the trim. A ship that was either heavy or down by the nose had to be held up by the use of the elevators. The buoyancy could be varied by valving gas (if light) or discharging ballast (if heavy). The trim depended initially on the way the ship was rigged, but could be varied, except when the envelope was full of gas, by the way the air was distributed between the two ballonets.

When the pilot wished to descend to a lower altitude, he first lowered the open end of the blower tube into the slip stream by releasing the toggle over the dashboard. The elevator wheel was then turned downwards and the crab pot toggle released. The air was then blown by the propeller along the air duct and through the open crab pot into the ballonet. The speed of descent was limited by the ability to blow in air fast enough to maintain the normal pressure. Unless the ship was heavy there was no tendency to accelerate in the dive.

Before landing, the pilot ballasted up carefully by laying the ship head to wind with the elevators in neutral and throttling back until the engine was ticking over slowly. The pressure gauge, and also the bubble statoscope, would then indicate whether the ship was rising or falling and thus whether she was light or heavy. The ship was then brought to a state of equilibrium by releasing ballast or gas as necessary, air being blown into the ballonets of course to replace any gas released. Accurate ballasting up was important; failure to do so could endanger not only the ship and crew but also members of the landing party. If the ship was heavy she would be liable to hit the ground when the engine was throttled back. On the other hand, if she was light to any extent she would be liable to rise before being properly secured and might take one of the landing party up on the trail rope or guys. The ideal state was to be a few pounds on the light side so that with the elevators down and the engine just ticking over the ship would remain stationary.

Landing a Zero was not a particularly difficult job provided that the aerodrome was sufficiently large and the wind steady. With a small aerodrome and a gusty wind it was not always so easy. Landing in a flat calm could also present difficulties to an inexperienced pilot. The method of landing involved the assistance of a landing party of from 20 to 30 men, depending on the wind strength. These were usually in the charge of a duty landing officer or petty officer. The men were formed up in a “V”, with the apex pointing as exactly as possible into the wind. If the aerodrome was provided with a snatch block to take the trail rope, the landing party formed up a little way in front of the block. A wooden arrow laid out on the ground also indicated the wind direction to the pilot.

Having ballasted up carefully, the pilot took his ship down wind so as to have a straight approach of about a quarter to half a mile to the landing point, the distance required depending on the wind strength. During the approach the pilot had firstly to lose altitude so as to be at a height of about 50 feet when over the landing party; secondly to reduce speed so that on reaching the landing party his ground speed was virtually nil, while at the same time maintaining sufficient steerage way to enable the ship to keep on a straight course. He had also to ensure that the gas pressure did not fall below the permissible limit during the descent. This involved nice judgement of the amount of engine to use, particularly if the wind was light. If too much was used the ship would approach the landing party at too high a speed for a safe landing, and the landing officer would order the party to open out and let the ship through to go round again and make another attempt. On the other hand, if too little engine was used, the ship would not answer to the rudder quickly enough and would probably swing off the wind at the critical moment. A short burst of engine would sometimes correct this situation without increasing the approach speed too much.

When over the landing party, the trail rope was dropped. The landing party immediately seized the trail rope, putting it through the snatch block if one was available, and hauled the ship down until the forward guys reached the ground. Part of the landing party was then detached to man the guys and the remainder formed the car party. In good weather an experienced pilot would often bring his ship straight down on the the guys without bothering to use the trail rope. This required accurate judgement of height and speed and careful steering.

On a night landing, the position of the landing party was indicated by a triangle of lights at the apex of the landing arrow, a red light on the port side of the approach path (as seen by the pilot) and a green light on the starboard side. The landing procedure was the same as in daylight. Night flying in clear weather presented no particular difficulties and night landings were common.

Captain F W Verry OBE

NS11 – As Bright As Day is very much a work in progress and has been made possible by the generous and enthusiastic support of many individuals and organisations. If you have any information, records or material relating to British NS Class airships we would be very interested to hear from you – especially anyone related to members of the crew of NS11 or any airship of the class during their service with the RNAS or RAF during and beyond WWI.

NS11 – As Bright As Day is very much a work in progress and has been made possible by the generous and enthusiastic support of many individuals and organisations. If you have any information, records or material relating to British NS Class airships we would be very interested to hear from you – especially anyone related to members of the crew of NS11 or any airship of the class during their service with the RNAS or RAF during and beyond WWI.

Latest